Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2021

Table of contents

- 1 Overview

- Overview

- 3 Uranium Processing Facilitie

- 4 Nuclear Substance Processing Facilities

- 5 CNSC Regulatory Oversight

- 6 The CNSC’s Assessment of Safety at Uranium and Nuclear Substance Processing Facilities

- 6.1 Management System

- 6.2 Human Performance Management

- 6.3 Operating Performance

- 6.4 Safety Analysis

- 6.5 Physical Design

- 6.6 Fitness for Service

- 6.7 Radiation Protection

- 6.8 Conventional Health and Safety

- 6.9 Environmental Protection

- 6.10 Emergency Management and Fire Protection

- 6.11 Waste Management

- 6.12 Security

- 6.13 Safeguards and Non-Proliferation

- 6.14 Packaging and Transport

- 7 Indigenous Consultation and Engagement

- 8 Events and Other Matters of Regulatory Interest

- 9 Overall Conclusions

- 10 References

- 11 Acronyms and Abbreviations

- 12 Glossary

- A. Links to Licensee Websites and Annual Compliance Reports

- B. CNSC Inspections

- C. Significant Changes to Licences and Licence Conditions Handbooks

- D. Regulatory Document Implementation

- E. Financial Guarantees

- F. Safety and Control Area Ratings

- G. Total Annual Releases of Radionuclides Directly to the Environment

- H. Public Dose Data

- I. Environmental Data

- J. Worker Dose Data

- K. Health and Safety Data

- L. Reportable Events

- M. Indigenous Nations, Communities and Organizations whose Traditional and/or Treaty Territories are in Proximity to Uranium and Nuclear Substance Processing Facilities Covered in the 2021 ROR

- N. Participant Funding Recipients for the 2021 UNSPF Regulatory Oversight Report

1.1 Changes to 2021 regulatory oversight report

As with other regulatory oversight reports produced by the Canadian Nuclear Safety Commission (CNSC), changes have been made to this report as a result of recommendations/direction from the Commission and feedback from intervenors. CNSC staff made the following changes to the Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2021:

- Land acknowledgements have been added in the facility description sections.

- Indigenous consultation and engagement has been made a stand-alone section.

- Collaborative reporting on long-term engagement activities with Indigenous Nations and communities has been provided.

- Summaries of the urine analysis results on the concentration of uranium in the urine of nuclear energy workers have been included.

Plain language summary

The Regulatory Oversight Report for Uranium and Nuclear Substance Processing Facilities in Canada: 2021 provides information on the safety performance of these types of nuclear facilities. The report is based on Canadian Nuclear Safety Commission (CNSC) staff’s work to ensure the health, safety and protection of the people and the environment around licenced uranium and nuclear substance processing facilities (UNSPFs). In 2021, all facilities operated safely. Monitoring data showed that the water and food grown nearby were safe for consumption. There were no releases from UNSPFs that could have harmed human health or the environment.

This report also provides an update on CNSC staff’s regulatory activities pertaining to public information, community engagement, and aspects of the CNSC’s Independent Environmental Monitoring Program that relate to UNSPFs. Where possible, trends are shown and information is compared to previous years.

This report provides information on the following licensed facilities in Canada:

- Uranium processing facilities

- Cameco Corporation Blind River Refinery, Blind River, Ontario

- Cameco Corporation Port Hope Conversion Facility, Port Hope, Ontario

- Cameco Fuel Manufacturing Inc., Port Hope, Ontario

- BWXT Nuclear Energy Canada Inc., Toronto, Ontario

- BWXT Nuclear Energy Canada Inc., Peterborough, Ontario

- Nuclear substance processing facilities

- SRB Technologies (Canada) Inc., Pembroke, Ontario

- Nordion (Canada) Inc., Ottawa, Ontario

- Best Theratronics Ltd., Ottawa, Ontario

- BWXT Medical Ltd., Ottawa, Ontario

Each year, CNSC inspectors and experts complete inspections at these facilities. The number and scope of inspections at each facility depend on the potential hazards (risks) the facility poses to people and the environment and its performance history. The CNSC uses a risk-informed approach when planning inspections. Over the reporting period, CNSC staff performed a total of 13 inspections at the UNSPFs. These inspections resulted in the issuance of 35 notices of non-compliance (NNCs), which were all related to issues identified as being of low safety significance. In addition, to ensure that non-proliferation obligations were met, 29 International Atomic Energy Agency–initiated safeguards verification activities and 1 CNSC-initiated safeguards field activity were performed at the UNSPFs. No NNCs resulted from these regulatory activities.

The CNSC uses 14 safety and control areas (SCAs) to evaluate the performance of each licensee; the resulting performance ratings are included in this report. Particular focus is placed on the radiation protection, environmental protection, and conventional health and safety SCAs, as these give a good overview of safety performance.

The SCA ratings in this report were derived from the results of activities conducted by CNSC staff to verify licensee compliance. These activities included onsite and virtual inspections, technical assessments, reviews of reports submitted by licensees, reviews of events and incidents, and ongoing exchanges of information with licensees. For the reporting period, CNSC staff rated all SCAs as satisfactory for all facilities covered in this report and confirmed that all were operating safely.

The facilities discussed in this report lie within the traditional and/or treaty territories of many Indigenous Nations and communities. In 2021, CNSC staff undertook ongoing and meaningful engagement activities with Indigenous Nations and communities in relation to the facilities covered by this regulatory oversight report. These engagement activities support the CNSC’s commitment to meeting its consultation responsibilities and continuing to build and strengthen positive relationships with Indigenous Nations and communities.

This report is available on the CNSC website, and the documents referenced in it are available upon request by contacting:

Senior Tribunal Officer, Commission Registry

Tel.: 613-858-7651 or 1-800-668-5284

Fax: 613-995-5086

Email: interventions@cnsc-ccsn.gc.ca

2 Overview

Through the application of the Nuclear Safety and Control Act (NSCA) Footnote 1 and its associated regulations, the Canadian Nuclear Safety Commission (CNSC) regulates Canada’s nuclear industry to protect the health and safety of persons and the environment and to implement Canada’s international commitments on the peaceful use of nuclear energy. The CNSC also disseminates objective scientific, technical and regulatory information to the public. Licensees are responsible for operating their facilities safely, and are required to implement programs that make adequate provision for meeting legislative and regulatory requirements and licence conditions.

This regulatory oversight report (ROR) provides an overview of CNSC regulatory efforts and staff’s assessment of uranium and nuclear substance processing facilities (UNSPFs) in Canada for the 2021 calendar year.

The facilities covered by this report are:

- Uranium processing facilities 1

- Cameco Corporation Blind River Refinery, Blind River, Ontario (FFOL-3632.00/2032)

- Cameco Corporation Port Hope Conversion Facility, Port Hope, Ontario (FFOL-3631.00/2027)

- Cameco Fuel Manufacturing Inc., Port Hope, Ontario (FFL-3641.00/2023)

- BWXT Nuclear Energy Canada Inc., Toronto, Ontario (FFL-3621.00/2030)

- BWXT Nuclear Energy Canada Inc., Peterborough, Ontario (FFL-3620.00/2030)

- Nuclear substance processing facilities 1

- SRB Technologies (Canada) Inc., Pembroke, Ontario (NSPFL-13.00/2034)

- Nordion (Canada) Inc., Ottawa, Ontario (NSPFOL-11A.01/2025)

- Best Theratronics Ltd., Ottawa, Ontario (NSPFOL-14.00/2029)

- BWXT Medical Ltd. (formally BWXT Technologies Ltd.), Ottawa, Ontario (NSPFL-15.00/2031)

1 Each alpha-numeric expression refers to the licence held by the licensee, where FFOL = fuel facility operating licence; FFL = fuel facility licence; and NSPFOL = nuclear substance processing facility operating licence.

This report discusses all safety and control areas (SCAs), but focuses on radiation protection, environmental protection, and conventional health and safety, as they provide a good overview of safety performance at licensed facilities. The report also provides an overview of licensee operations, licence changes, major developments at licensed facilities and sites, and reportable events. In addition, the report includes information on engagement with Indigenous Nations and communities, public information programs, and COVID-19 responses by the CNSC and the licensees.

3 Uranium processing facilities

Uranium processing facilities are part of the nuclear fuel cycle that includes refining, conversion and fuel manufacturing. The fuel produced is used in nuclear power plants for the generation of electricity.

3.1 Cameco Blind River Refinery

Cameco Corporation owns and operates the Blind River Refinery (BRR), in Blind River, Ontario. The facility is located about 5 km west of the town of Blind River and south of Mississauga First Nation, as shown in figure 2-1. The facility is located within the Robinson-Huron and Robinson-Superior Treaties territory and the traditional territory of the Anishinabek, Métis and Odawa peoples, in particular Mississauga First Nation.

(Source: Cameco)

The BRR facility refines uranium concentrates (yellowcake) received from uranium mines in Canada and around the world to produce uranium trioxide (UO3), an intermediate product of the nuclear fuel cycle. The primary recipient of the UO3 is Cameco’s Port Hope Conversion Facility.

In 2021, CNSC staff conducted 2 inspections at the BRR that covered 8 SCAs. Table B-1 in appendix B lists these inspections and the 9 resulting notices of non-compliance (NNCs).

CNSC staff are satisfied that Cameco’s BRR operated safely in 2021 and in accordance with its licensing basis.

3.1.1 2021 BRR licence renewal

In November 2021, the Commission conducted a virtual public hearing on the renewal of Cameco’s BRR operating licence. CNSC staff’s assessment of the renewal application was presented publicly during the hearing as Commission member document CMD 21-H9.

In February 2022, the Commission made a decision on the Cameco BRR licence renewal application, as documented in the Record of Decision. In its decision, the Commission renewed Cameco’s BRR licence (FFL-3632.00/2032) for a period of 10 years and accepted the proposed new financial guarantee.

3.2 Cameco Port Hope Conversion Facility

Cameco Corporation owns and operates the Port Hope Conversion Facility (PHCF), which is located in Port Hope, Ontario, within the traditional territory of the Wendat, Anishinabek Nation, and the territory covered by the Williams Treaties with the Michi Saagiig and Chippewa Nations. The facility is situated on the north shore of Lake Ontario, approximately 100 km east of Toronto. Figure 2‑2 shows an aerial view of the PHCF.

(Source: Cameco)

PHCF converts UO3 powder produced by Cameco’s BRR into uranium dioxide (UO2) and uranium hexafluoride (UF6). UO2 is used in the manufacturing of Canada Deuterium Uranium (CANDU) reactor fuel, while UF6 is exported for further processing before being converted into fuel for light-water reactors.

In 2021, CNSC staff conducted 4 inspections at PHCF that covered 10 SCAs, as well as compliance verification activities associated with the Vision in Motion project (discussed below). Table B-2 in appendix B lists these inspections and the 15 resulting NNCs.

CNSC staff are satisfied that Cameco’s PHCF operated safely in 2021 and in accordance with its licensing basis.

Vision in Motion

Vision in Motion (VIM) is Cameco’s project to clean up and renew the PHCF site. The project builds on work now underway through the Port Hope Area Initiative to address historic low-level radioactive waste issues in the Municipality of Port Hope. The VIM project is being carried out under Cameco’s operating licence, FFOL-3631.00/2027. Licence condition 16.1 states: "The licensee shall implement and maintain a program to carry out clean-up, decontamination and remediation work". VIM activities were significantly impacted by the continuing COVID-19 pandemic. Mobilization of field crews in early 2021 was deferred, and onsite activities were restricted to maintaining the project work areas in a safe condition and some other limited work. Crews began to remobilize in September 2021. In 2021, Cameco carried out VIM work that included:

- the preparation and transfer of stored wastes to the CNSC-licensed Canadian Nuclear Laboratories (CNL) Port Hope Project Long-Term Waste Management Facility (LTWMF); packaged waste shipments to the LTWMF were suspended temporarily in 2021 until a new waste cell was made available

- the removal of interior equipment and accumulated waste materials in Building 27 (the former UF6 plant)

- the installation of infrastructure, including the completion of outstanding construction on the new liquid hydrogen area (stage 1 commissioning initiated), feasibility-level engineering design and construction planning for the parking lot storm-water sewer system, and an early contractor involvement planning package for the deep excavation west of the harbour turning basin

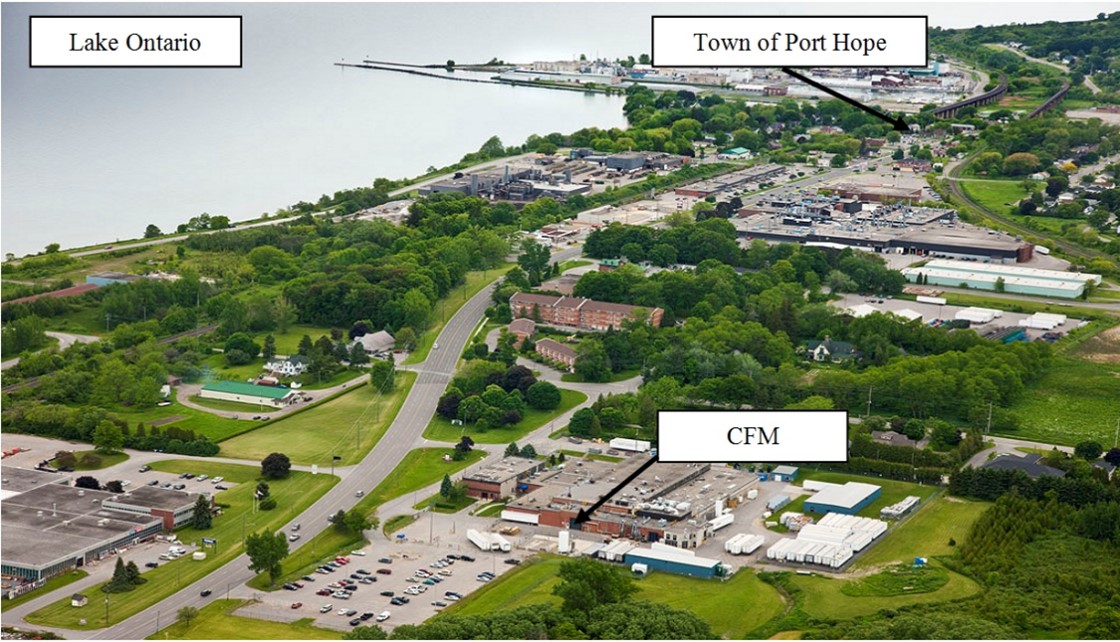

3.3 Cameco Fuel Manufacturing Inc.

Cameco Fuel Manufacturing Inc. (CFM) is a wholly owned subsidiary of Cameco Corporation. CFM is located within the same Indigenous traditional and treaty territory as PHCF. CFM operates 2 facilities: a nuclear fuel fabrication facility licensed by the CNSC in Port Hope, Ontario (referred to as CFM in this report); and a metals manufacturing facility in Cobourg, Ontario, which manufactures fuel bundle and reactor components. This latter facility is not licensed by the CNSC and is not discussed further in this report. Figure 2-3 shows an aerial view of the CFM facility.

(Source: Cameco)

The CFM facility manufactures fuel pellets from UO2 powder and assembles nuclear reactor fuel bundles. The finished fuel bundles are primarily shipped to Canadian nuclear power reactors.

In 2021, CNSC staff conducted 2 inspections at CFM that covered 2 SCAs. Table B-3 of appendix B lists these inspections and the 9 resulting NNCs.

CNSC staff are satisfied that CFM operated safely in 2021 and in accordance with its licensing basis.

3.3.1 2021 CFM licence renewal

In December 2020, Cameco submitted an application for the renewal of CFM’s Class IB fuel facility licence for a 1-year period. The 1-year licence term was requested to separate CFM from the ongoing licence renewal activities for Cameco’s BRR. Following a review of Cameco’s application and supporting documents, CNSC staff’s findings and recommendations were documented in CMD 21-H105, which was reviewed by the Commission at a hearing in writing following a 60-day intervention period. In February 2022, the Commission issued its decision (Record of Decision), granting a 1-year renewal of the CFM licence, which expires on February 28, 2023.

In October 2021, Cameco submitted an application for a 20-year renewal of the CFM licence. In its application, Cameco requested an increase to the production limit from 125 tonnes of UO2 as pellets during any calendar month to 1,650 tonnes of uranium as UO2 pellets per year. CNSC staff’s CMD will be available on the CNSC website after August 9, 2022, and the deadline for written interventions is October 7, 2022. A Commission hearing is scheduled for November 23–24, 2022, to consider submissions from Cameco and CNSC staff, as well as interventions from the public and Indigenous Nations and communities.

3.4 BWXT Nuclear Energy Canada Inc.

BWXT Nuclear Energy Canada Inc. (BWXT NEC) produces nuclear fuel and fuel bundles used by Ontario Power Generation’s Pickering and Darlington nuclear generating stations. BWXT NEC has licensed operations in 2 locations: Toronto and Peterborough, Ontario. Figures 2-4 and 2-5 show aerial views of the BWXT NEC facilities. The Toronto facility is located within the traditional territory of the Mississaugas of the Credit, the Anishnabeg, the Chippewa, the Haudenosaunee and the Wendat peoples, and is now home to many diverse First Nations, Inuit and Métis peoples. The Peterborough facility resides in the traditional territory of the Michi Saagiig Anishinaabe people. These lands are covered by the Williams Treaty between Canada and the Mississaugua and Chippewa Nations.

(Source: Google Maps)

(Source: Google Earth)

The Toronto facility produces CANDU nuclear fuel pellets using UO2 supplied by PHCF. The Peterborough facility manufactures CANDU nuclear fuel bundles using the uranium pellets from Toronto and zircaloy tubes manufactured in-house. The Peterborough facility also runs a fuel services business involved with the manufacturing and maintenance of equipment for use in nuclear power plants

BWXT NEC has 2 licences issued by the Commission in December 2020, 1 for Toronto and 1 for Peterborough. Therefore, 2021 was the first year of operation under the new licences, and the licensee submitted 1 annual compliance report for each licence.

In 2021, CNSC staff conducted several outreach activities related to BWXT NEC’s licence renewal, beryllium soil sampling, and operations as directed by the Commission in its Record of Decision. These activities were summarized and reported to the Commission as part of the 2020 regulatory oversight report presentation during the December 2021 Commission meeting. Additional details on this outreach are provided in section 7.2.2.

In 2021, CNSC staff conducted 1 inspection at BWXT NEC that covered 2 SCAs. Table B-4 in appendix B lists these inspections and the 1 resulting NNC.

CNSC staff are satisfied that the BWXT NEC facilities operated safely in 2021 and in accordance with their licensing basis.

4 Nuclear substance processing facilities

Nuclear substance processing facilities use nuclear substances to manufacture various products for end uses in industrial or medical applications. The nuclear substances can be used for lighting self-luminous emergency and exit signs, sterilizing items such as surgical gloves for sanitary reasons, and providing cancer diagnosis and treatment. All of the facilities are located within the traditional unceded territory of the Algonquin Anishinaabeg peoples.

4.1 SRB Technologies (Canada) Inc.

SRB Technologies (Canada) Inc. (SRBT) operates a Class IB facility manufacturing gaseous tritium light sources (GTLSs) on the outskirts of Pembroke, Ontario, located approximately 150 km northwest of Ottawa. The nuclear facility has been in operation since 1990. Figure 3-1 shows an aerial view of the SRBT facility.

(Source: SRBT)

The SRBT facility processes tritium gas (HT) to produce sealed glass capsules coated with phosphorescent powder and filled with HT to generate continuous light. Examples of such GTLSs include signs, markers and tactical devices. SRBT distributes its products in Canada and internationally

In 2021, CNSC staff conducted 3 inspections at SRBT that covered 2 SCAs. Table B-5 in appendix B lists these inspections and the 1 resulting NNC.

CNSC staff are satisfied that SRBT operated safely in 2021 and in accordance with its licensing basis.

4.1.1 2021 SRBT licence renewal

In June 2021, CNSC staff received SRBT’s application for a 15-year renewal of its nuclear substance processing facility operating licence. In April 2022, the Commission conducted a virtual public hearing on the renewal of SRBT’s operating licence. CNSC staff’s assessment of the renewal application was presented publicly during this hearing as CMD 22-H8.

In June 2022, the Commission made a decision on SRBT’s licence renewal application, as documented in the Record of Decision. In its decision, the Commission renewed the licence (NSPFL-13.00/2034) for a period of 12 years.

4.2 Nordion (Canada) Inc.

Nordion (Canada) Inc. (Nordion) is located in Ottawa, Ontario, and is licensed to operate a Class IB nuclear substance processing facility. Figure 3-2 shows an aerial view of the Nordion facility.

(Source: Google Maps)

Nordion provides cobalt-60 (Co-60) and gamma irradiation systems for medical devices, food safety and health care industries, and innovative applications.

In 2018, the medical isotope segment of Nordion’s business was sold to BWXT Technologies, Inc. (now BWXT Medical Ltd.). Nordion is no longer licensed to operate the medical isotope facility as BWXT Medical Ltd. was granted a licence from the Commission to do so in November 2021, as documented in the Record of Decision.

There were no inspections conducted by CNSC staff at Nordion in 2021.

On the basis of the compliance verification work performed in 2021, CNSC staff are satisfied that Nordion operated safely and in accordance with its licensing basis.

4.3 Best Theratronics Ltd.

Best Theratronics Ltd. (BTL) operates a Class 1B facility manufacturing medical devices in Ottawa, Ontario. Figure 3-3 shows an aerial view of the BTL facility.

(Source: Google Maps)

BTL manufactures cyclotrons and medical equipment, including cobalt‑60 (Co‑60) based external beam radiation therapy units and cesium-137 (Cs-137) self-contained irradiators for blood irradiation.

In 2021, CNSC staff conducted 1 inspection at BTL that covered 1 SCA. Table B‑6 in appendix B lists this inspection and there were no resulting NNCs

CNSC staff are satisfied that BTL operated safely in 2021 and in accordance with its licensing basis.

4.4 BWXT Medical Ltd.

BWXT Medical Ltd. (formally BWXT Technologies Ltd.) operates a Class IB nuclear substance processing facility in Ottawa, Ontario.

(Source: Google Maps)

BWXT Medical Ltd. processes unsealed radioisotopes such as yttrium-90 and indium-111 for health and life sciences applications. The facility is composed of a nuclear medicine production facility where the radioisotopes used in nuclear medicine are processed.

No inspections were performed at the BWXT Medical facility in 2021 as it was operating under Nordion’s operating licence from January 1, 2021, to October 31, 2021.

CNSC staff are satisfied that BWXT Medical Ltd. operated safely in 2021 and in accordance with its licensing basis.

4.4.1 2021 BWXT Medical licence issuance

In August 2018, BWXT Medical Ltd. acquired Nordion’s medical isotope business. In December 2018, BWXT Medical applied for its own Class IB operating licence.

In June 2021, the Commission conducted a virtual public hearing on BWXT Medical’s Class 1B operating licence application. CNSC staff’s assessment of the application was presented publicly during this hearing as CMD 21-H5.

In October 2021, the Commission made a decision on BWXT Medical’s licence application, as documented in the Record of Decision. In its decision, the Commission issued BWXT Medical a licence (NSPFL-15.00/2031) for a period of 10 years and accepted the proposed financial guarantee.

5 CNSC regulatory oversight

The CNSC performs regulatory oversight of licensed facilities to verify compliance with the requirements of the NSCA and the associated regulations made under it, each site’s licence and licence conditions, and any other applicable standards and regulatory documents.

CNSC staff use the SCA framework to assess, evaluate, review, verify and report on licensee performance. The SCA framework includes 14 SCAs, which are subdivided into specific areas that define each SCA’s key components. Further information on the SCA framework can be found on the CNSC’s website.

5.1 Regulatory activities

CNSC staff conducted many risk-informed regulatory oversight activities at Canada’s UNSPFs in 2021. Table 4-1 presents CNSC staff’s licensing and compliance verification efforts for these facilities for the reportable year.

| Licensee | Number of inspections | Person-days for compliance verification activities | Person-days for licensing activities | Number of IAEA-initiated safeguards verification activities | Number of CNSC-initiated safeguards field activities |

|---|---|---|---|---|---|

| BRR | 2 | 165.30 | 376.2 | 7 | 0 |

| PHCF | 4 | 387.07 | 2.40 | 10 | 0 |

| CFM | 2 | 219.43 | 147.63 | 4 | 0 |

| BWXT NEC | 1 | 190.6 | 50.7 | 8* | 1** |

| SRBT | 3 | 157.13 | 194.73 | 0 | 0 |

| Nordion | 0 | 74.67 | 1.87 | 0 | 0 |

| BTL | 1 | 126.30 | 0.27 | 0 | 0 |

| BWXT Medical | 0 | 34.87 | 230.20 | 0 | 0 |

*Four IAEA-initiated inspections at Toronto and four at Peterborough (IAEA = International Atomic Energy Agency).

**One CNSC-initiated inspection at Toronto.

Compliance verification

The CNSC ensures licensee compliance through verification, enforcement and reporting activities. CNSC staff implement compliance plans for each site by conducting regulatory activities, including inspections, desktop reviews, and technical assessments of licensee programs, processes and reports.

Appendix A contains a list of annual compliance reports prepared by the licensees for the period from January to December 2021

Appendix B contains a list of CNSC inspections carried out at UNSPFs in 2021. The majority of findings in these inspections were considered to be of low risk, with 2 being of medium risk, and none had an impact on safety at the facilities.

Licensing

CNSC staff’s licensing activities include drafting new or amended licences, preparing CMDs, and drafting or revising licence conditions handbooks (LCHs).

When CNSC regulatory documents are published, CNSC staff update the LCHs as applicable for each site, taking into consideration the licensee’s implementation plans. Appendix C provides a list of changes to UNSPF licences and LCHs. CNSC staff verify the implementation as part of ongoing compliance verification activities. Appendix D provides a list of CNSC regulatory documents implemented in 2021 at UNSPFs and used by CNSC staff for compliance verification. Appendix E presents the financial guarantee amounts for each facility.

IAEA safeguards activities

Under the terms of the Canada–IAEA safeguards agreements, the IAEA performs verification activities to confirm that all nuclear material in Canada remains in peaceful use. The CNSC regulatory framework requires Canadian operators to provide the access, assistance and information required for the IAEA to complete its activities. CNSC staff ensure operator compliance with these requirements.

5.2 Performance ratings, 2021

CNSC staff assign performance ratings to licensees based on the results of regulatory oversight activities.

These ratings are either "satisfactory" (SA) or "below expectations" (BE) for the UNSPF (2021). The "fully satisfactory" (FS) rating has not been in use since 2019.

For 2021, CNSC staff rated the performance in each SCA as SA for all UNSPFs. Appendix F provides the SCA ratings for each licensee from 2017 to 2021.

6 CNSC assessment of safety at uranium and nuclear substance processing facilities

The CNSC regulates all aspects of safety at nuclear sites in Canada, including risks to workers, the public and the environment. All 14 SCAs, discussed in the following paragraphs, have been assessed. Detailed information is provided on radiation protection, conventional health and safety, and environmental protection, since these 3 SCAs are considered the most indicative of safety performance at UNSPFs. In particular, the SCAs of radiation protection and conventional health and safety are a good measure of the safety of workers, while the SCA of environmental protection is an appropriate measure of the safety of people and the environment.

6.1 Management system

The management system SCA covers the framework that establishes the processes and programs required to ensure that an organization achieves its safety objectives, continuously monitors its performance against these objectives, and fosters a healthy safety culture.

CNSC staff assess performance in the management system SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. The specific areas assessed within the management system include organization; planning and controlling business activities; resource management; communication; safety culture; change management; information management; work management; problem identification and resolution; and performance assessment, improvement and management review.

NNCs from inspections related to the management system SCA were issued for the following licensees over the reporting period:

- PHCF – 3 NNCs related to document review processes (documenting processes, timeliness, traceability and transparency)

- SRBT – 1 NNC related to ensuring that supplier evaluations are performed to confirm the initial and ongoing acceptability of the supplier’s management system

- BWXT NEC – 1 NNC related to the frequency of reviewing elements of the management system

The licensees have taken all necessary corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facilities.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained and implemented satisfactory management system programs for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.2 Human performance management

The human performance management SCA covers activities that enable effective human performance through the development and implementation of processes that ensure a sufficient number of licensee personnel are in all relevant job areas and have the necessary knowledge, skills, procedures and tools in place to safely carry out their duties.

CNSC staff assess performance in the human performance management SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. For this SCA, CNSC staff verify that licensees are in compliance with REGDOC-2.2.2, Personnel Training [2], and their documented personnel training programs.

NNCs from inspections related to the human performance management SCA were issued for the following licensees over the reporting period:

- CFM – 5 NNCs related to the documentation and records for the systematic approach to training (SAT) implemented onsite

- PHCF – 4 NNCs based on findings related to the SAT-based personnel training program

The licensees have taken all necessary corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facilities.

CNSC staff concluded that the UNSPFs implemented and maintained effective programs specific to personnel training and met regulatory requirements. CNSC staff will continue to verify that licensees are in compliance with the requirements for their programs and procedures, as part of ongoing regulatory oversight activities.

6.3 Operating performance

The operating performance SCA includes an overall review of the conduct of the licensed activities and the activities that enable effective performance.

CNSC staff assess performance in the operating performance SCA by verifying that policies, programs, methods and procedures are in place for the safe operation and maintenance of nuclear facilities. Verification of compliance with the requirements of this SCA is included as part of the CNSC’s compliance verification activities, including desktop reviews of annual reports, reviews of event reports and related corrective actions, and planned or reactive inspections.

There were no NNCs from inspections related to the operating performance SCA for the licensees covered in this report. CNSC staff concluded that the UNSPFs implemented and maintained effective operating programs in order to ensure that licensed activities are conducted safely and in compliance with regulatory requirements. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.4 Safety analysis

The safety analysis SCA includes maintenance of the safety analysis that supports the overall safety case for the facility. Safety analysis is a systematic evaluation of the potential hazards associated with the conduct of a proposed activity or facility and considers the effectiveness of preventive measures and strategies in reducing the effects of such hazards.

CNSC staff assess performance in the safety analysis SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify that licensees maintain safety analysis reports (SARs) that include updated information on the description of the facility and the measures in place to protect the safety of workers, the public and the environment under normal operations, abnormal operations and accident conditions. CNSC staff asses the SARs to ensure that they provide an assessment of the potential consequences and demonstrate the safety case through defence in depth.

There were no NNCs from inspections related to the safety analysis SCA for the licensees covered in this report. CNSC staff concluded that the UNSPFs met regulatory requirements and maintained satisfactory ratings in the safety analysis SCA for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.5 Physical design

The physical design SCA relates to activities that affect the ability of structures, systems and components to meet and maintain their design basis, given new information arising over time and taking changes in the external environment into account.

CNSC staff assess performance in the physical design SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify compliance with the physical design SCA requirements by ensuring the implementation of national codes and standards for structural design and by maintaining authorized inspection agency formal agreements, including those relating to pressure-retaining programs where applicable.

There were no NNCs from inspections related to the physical design SCA for the licensees covered in this report. CNSC staff concluded that the UNSPFs met regulatory requirements and maintained satisfactory ratings in the physical design SCA for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.6 Fitness for service

The fitness for service SCA covers activities that affect the physical condition of structures, systems and components to ensure that they remain effective over time. This includes programs that ensure that all equipment is available to perform its intended design function when called upon to do so.

CNSC staff assess performance in the fitness for service SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff verify that the programs cover activities that affect the physical condition of structures, systems and components over time. Specific areas are assessed within this SCA to ensure that the fitness for service programs are supported by detailed procedures on preventative maintenance, the measuring and testing of equipment, and new equipment validation.

An NNC from inspections related to the fitness for service SCA was issued for the following licensee over the reporting period:

- BRR – 1 NNC related to timeliness in addressing identified moderate- to high-risk deficiencies

The licensee has taken all necessary corrective actions to address the above-noted NNC. The finding was of medium safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facility.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained satisfactory ratings in the fitness for service SCA for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

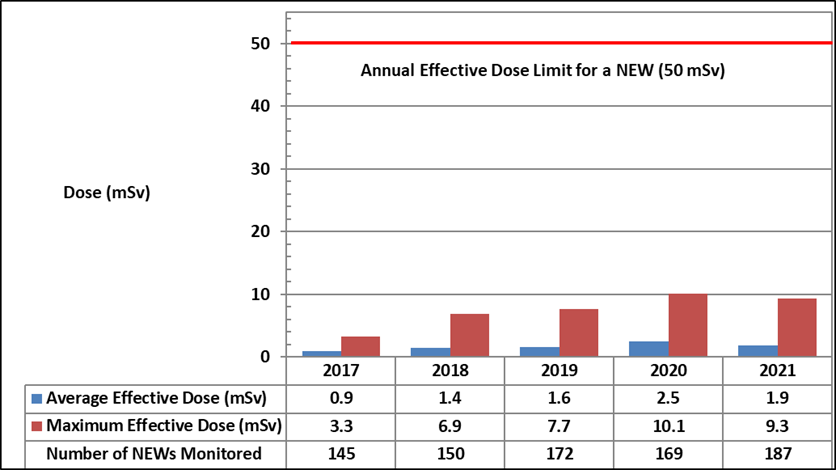

6.7 Radiation protection

The radiation protection SCA covers the implementation of a radiation protection program in accordance with the Radiation Protection Regulations Footnote 3. The program must ensure that contamination levels and radiation doses received by individuals are monitored, controlled and maintained as low as reasonably achievable (ALARA).

NNCs from inspections related to the radiation protection SCA were issued for the following licensees over the reporting period:

- BRR – 1 NNC related to the frequency of reviews of the contractor orientation workbook and quick reference card

- PHCF – 1 NNC related to surface contamination within the UF6 and UO2 plant operations

The licensees have taken corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facilities. CNSC staff rated the radiation protection SCA at all UNSPFs as satisfactory.

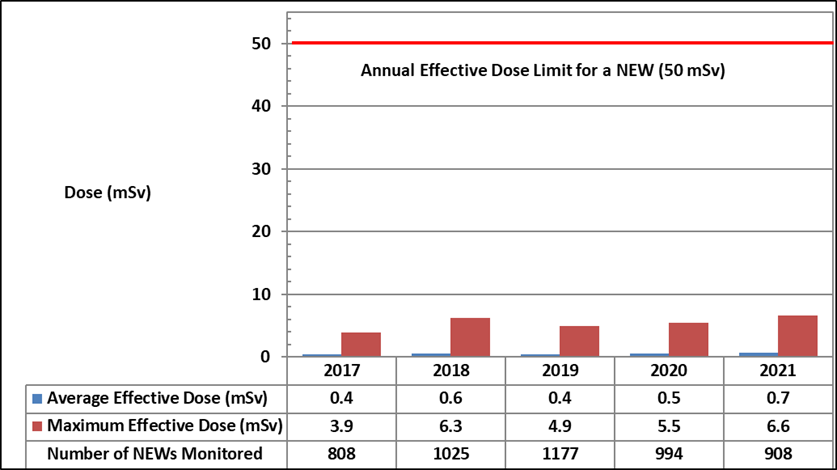

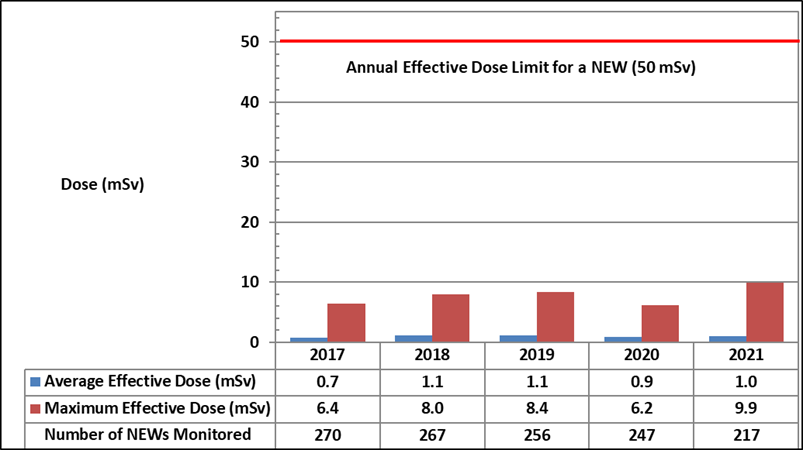

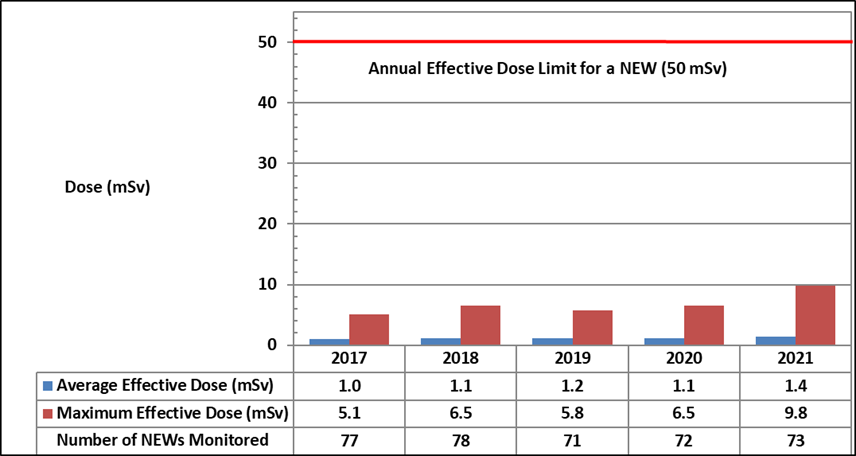

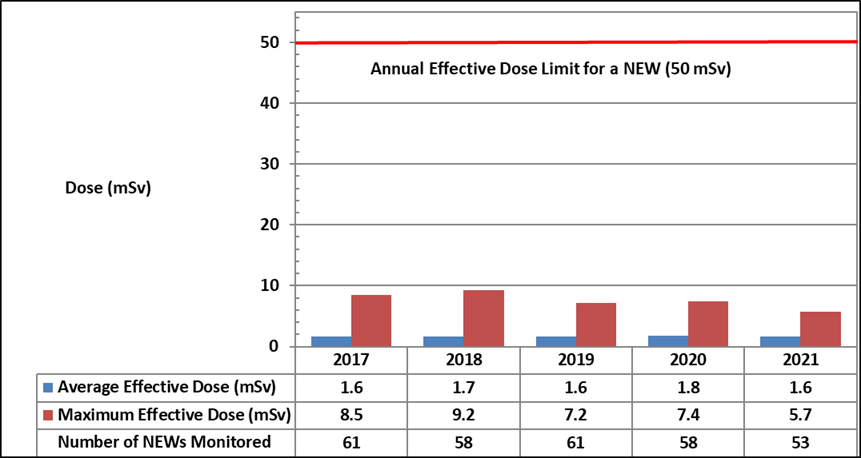

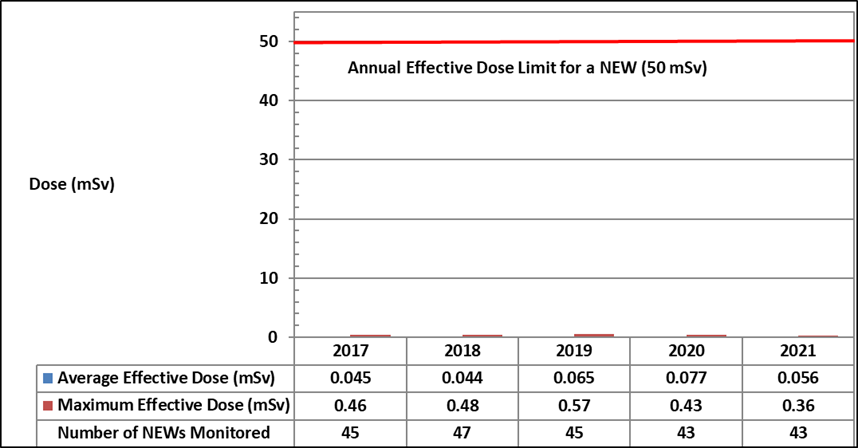

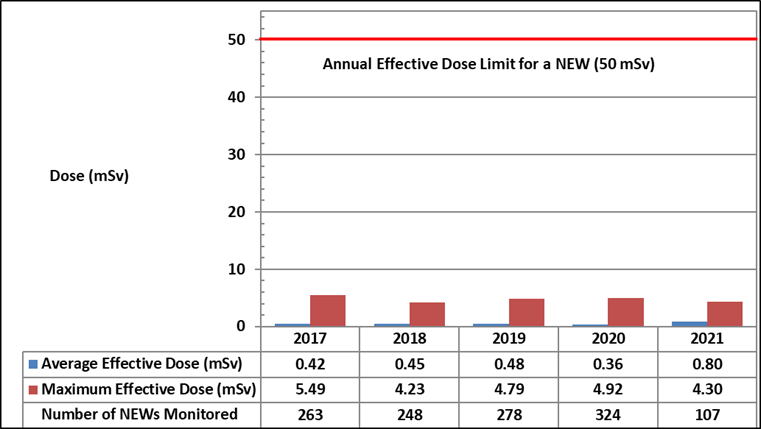

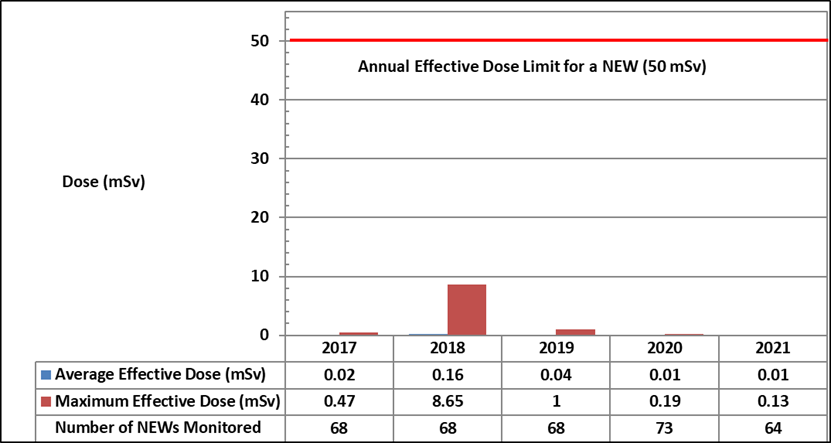

Appendix J contains data on doses to workers for the UNSPFs from 2017 to 2021.

Application of ALARA

CNSC staff confirmed that all UNSPFs continued to implement radiation protection measures to keep radiation exposures and doses to persons ALARA. The CNSC requirement for licensees to apply the ALARA principle has consistently resulted in these doses staying well below regulatory dose limits.

Worker dose control

Radiation protection programs include dosimetry methods, identification of workers requiring nuclear energy worker (NEW) status, and the methods for radiation safety of workers. Radiation protection programs vary, depending on the radiological hazards present and the expected magnitude of doses received by workers. CNSC staff confirmed that all UNSPFs monitored and controlled the radiation exposures and doses received by all persons present at their licensed facilities, including workers, contractors and visitors. Direct comparison between facilities of doses received by NEWs does not necessarily provide an appropriate measure of a licensee’s effectiveness in implementing its radiation protection program, since radiological hazards differ across these facilities due to complex and varying work environments.

In this report, summaries of the urine analysis results on the concentration of uranium in the urine of NEWs at the uranium processing facilities have been provided at the direction of the Commission, as set out in the BRR Record of Decision. This is new information to complement the worker dose statistics reported in Appendix J. For each uranium processing facility, a summary of the urine analysis program is provided, along with the urine analysis results for the years 2017 to 2021.

The urine analysis program at each uranium processing facility is unique and has been designed to monitor worker exposures resulting from chronic and acute inhalation and ingestion of uranium products. The purpose of the urine analysis program is two-fold, in that it may be used for dosimetric purposes and for monitoring concentrations of uranium in urine that could be indicative of chemical toxicity. Note that each program has varying inputs that result in identical action levels being associated with a different assigned dose or kidney burden.

The general classification system for inhaled compounds according to their solubility or retention in the human body is as follows: type F (fast), type M (medium), and type S (slow). Uranium products of all solubilities are found in CNSC-licensed uranium processing activities. With the exception of inhaled insoluble (i.e., type S) uranium compounds, the chemical toxicity of uranium to the kidneys is more of a concern from a health perspective than its radiological characteristics. For all uranium processing facility licensees, the action levels for uranium concentrations in urine are set at levels that consider the corresponding chemical toxicity reference limit of 3 µg of uranium per gram (U/g) of kidney tissue Footnote 4. This chemical toxicity reference limit is based on a vast body of peer-reviewed literature and is accepted internationally. It limits potential reversible and irreversible effects to the kidneys resulting from uranium’s chemical toxicity as a heavy metal. Remaining below this limit has been shown to be protective in situations of either acute or chronic exposures to uranium.

In 2021, no worker urine samples exceeded the action level for uranium at any of the uranium processing facilities.

Radiation protection program performance

CNSC staff conducted regulatory oversight activities at the UNSPFs to verify that the licensees’ radiation protection programs complied with regulatory requirements. These oversight activities included inspections, desktop reviews, and compliance verification activities specific to radiation protection. Through these activities, CNSC staff confirmed that all licensees have effectively implemented their radiation protection programs to control occupational exposures to workers and keep doses ALARA.

Action levels

The following radiation protection action level exceedances were reported to the CNSC:

- In June 2021, a CFM worker’s lung dose assignment was determined to be 5.9 mSv, which exceeds the annual action level of 5 mSv for lung dose. Cameco’s investigation into the exceedance identified that a requirement for the use of respiratory protection during a specific work activity was not included in the work instruction for the activity, nor was it part of the worker training and supervisor oversight activities. Corrective actions were implemented, including updating the work instructions for this work activity to include the respirator requirement and communicating this requirement to workers and supervisors.

- In November 2021, a PHCF worker’s whole-body dosimeter recorded a dose of 2 mSv, which is the monthly action level for whole-body dose. Cameco’s investigation identified that the worker performed work activities with the potential for increased external radiation exposures. Corrective actions were implemented, including updating the work instructions for these work activities to include the use of direct-reading dosimeters to track radiation doses in real time. This will make it easier for immediate action to be taken if worker doses approach and/or reach a pre-set cumulative dose control limit.

Radiological hazard control

CNSC staff verified that UNSPFs continued to implement adequate measures to monitor and control radiological hazards in their facilities. These measures included delineation of zones for contamination control purposes and in-plant air-monitoring systems. Licensees demonstrated that they have implemented workplace monitoring programs to protect workers. The licensees have also demonstrated that levels of radioactive contamination were below limits within their facilities throughout the year.

Conclusion

CNSC staff concluded that the UNSPFs implemented and maintained effective radiation protection programs for the reportable year. The licensees’ programs are effective in ensuring the health and safety of persons working in their facilities. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.8 Conventional health and safety

The conventional health and safety SCA covers the implementation of a program to manage workplace safety hazards and to protect workers.

Based on regulatory oversight activities, CNSC staff rated the performance of all UNSPFs as "satisfactory" for the conventional health and safety SCA.

Appendix K contains health and safety information for each UNSPF from 2017 to 2021.

Performance

Employment and Social Development Canada (ESDC) and the CNSC regulate conventional health and safety programs at UNSPFs. CNSC staff monitor compliance with regulatory reporting requirements and, when a concern is identified, consult with ESDC staff.

Licensees are required to report to the CNSC as directed by section 29 of the General Nuclear Safety and Control Regulations Footnote 5, including reports on serious illnesses or injuries incurred or possibly incurred as a result of a licensed activity.

A key performance measure for the conventional health and safety SCA is the number of lost-time injuries (LTIs) that occur per year. An LTI is an injury that takes place at work and results in the worker being unable to return to work to carry out their duties for a period of time. LTIs were recorded for the following licensees over the reporting period:

- BWXT NEC Peterborough – 1 LTI where a worker handling pneumatic piping experienced back pain and stiffness executing a non-licensed activity, resulting in 2 days of lost time

- BWXT Medical – 1 LTI where an employee overexerted their arm attempting to open a hot cell door incorrectly, resulting in 3 days of lost time

Practices

Licensees are responsible for developing and implementing conventional health and safety programs for the protection of their workers. These programs must comply with Part II of the Canada Labour Code Footnote 6.

CNSC staff conducted desktop reviews and inspections at all UNSPFs to verify the compliance of the licensees’ conventional health and safety programs with regulatory requirements.

An NNC from inspections related to the conventional health and safety SCA was issued for the following licensee over the reporting period:

- PHCH – 1 NNC related to the identification and labelling of confined spaces

The licensee has taken all necessary corrective actions to address the above-noted NNC. The finding was of low safety significance and did not affect the health and safety of workers, people or the environment, or the safe operation of the facility.

CNSC staff concluded, based on regulatory oversight activities, that the UNSPFs met all regulatory requirements for this specific area.

Awareness

Licensees are responsible for ensuring that workers have the knowledge to identify workplace hazards and take the necessary precautions to protect against those hazards. This is accomplished through training and ongoing internal communications with workers.

During inspections, CNSC staff verify that workers are trained to identify hazards at the facilities. CNSC staff confirmed that the UNSPFs have effectively implemented their conventional health and safety programs to keep workers safe.

Action levels

The following action level exceedance was reported to the CNSC:

- In August 2021 at PHCF, the urine analysis action level of 7 milligrams of fluoride per litre (7 mg F/L) of urine was reached when a contract worker’s post-shift urine sample result was 8.3 mg F/L. It should be noted that no symptoms of acute exposure to fluoride would be expected at this level (e.g., abdominal pain, nausea, vomiting, diarrhea), and further, no symptoms were displayed by the worker. The worker was performing work involving a significant amount of welding, using welding rods containing calcium fluoride. Cameco’s investigation determined that the welding rods were the source of the fluoride exposure, as it was found that the worker had removed their respirator periodically during welding activities. Corrective actions were implemented, including a stand-down with the contracted workers to share what was learned and to reinforce the importance of wearing a respirator. In addition, extra ventilation in the work area was deployed, and signage was posted reminding anyone entering the work area that respirator use is mandatory. Cameco was able to share this industrial hygiene finding with the contractor, which will enable it to take the lessons learned from this event and apply them to future job sites.

Conclusion

CNSC staff concluded that the UNSPFs implemented their conventional health and safety programs satisfactorily for the reportable year. The programs are effective in protecting the health and safety of persons working in these facilities. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.9 Environmental protection

Protection of the environment and the public are linked in the environmental protection SCA. This SCA covers programs that identify, control and monitor all releases of radioactive and hazardous substances and the effects on the environment and people from facilities or as a result of licensed activities.

NNCs from inspections related to the environmental protection SCA were issued for the following licensee over the reporting period:

- CFM – 4 NNCs related to:

- the accuracy of program documentation on sampling of a previous discharge point

- revisions to the waste treatment effluent discharge record to improve clarity in requirements

- maintaining the required frequency for in-plant fixed-air sampling

- ensuring consistency between current practice and documented requirements pertaining to air sampler calibrations

The licensee has taken all necessary corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people, the environment, or the safe operation of the facility.

Currently, all licensees covered by this ROR have acceptable environmental protection programs in place to ensure the protection of the public and the environment. CNSC staff rated the environmental protection SCA at all UNSPFs as satisfactory.

Appendix G provides the total annual releases of radionuclides for the UNSPFs from 2017 to 2021. Appendix H contains data on dose to the public from 2017 to 2021. Appendix I contains supplemental environmental data for all licensees.

Effluent and emissions control (releases)

All UNSPFs implement effluent monitoring programs commensurate with the risks of their operations. Airborne and waterborne releases of radioactive and hazardous substances at UNSPFs remained below regulatory limits in 2021.

Action levels

Action levels are a tool used to ensure that licensees are operating their facilities appropriately, in accordance with their approved program(s) and within the design and operational parameters of their wastewater treatment and air pollution control systems.

Action levels serve as an early warning system to ensure that licensees are carefully monitoring their operations and performance to prevent release limits from being exceeded. Action level exceedances are reportable to the CNSC.

Each licensee is responsible for identifying the parameters of its own program(s) to represent timely indicators of potential losses of control of the program(s). These licensee-specific action levels may also change over time, depending on operational and radiological conditions.

If an action level is reached, it triggers the licensee to determine the cause, notify the CNSC and, if applicable, take corrective action to restore the effectiveness of the environmental protection program. It is important to note that occasional action level exceedances indicate that the action level chosen is likely an adequately sensitive indicator of a potential loss of control of the program.

Licensee performance is not evaluated on the number of action level exceedances in a given period, but rather, on how the licensee responds and implements corrective actions to enhance program performance and prevent reoccurrence. Licensees are required to periodically review their action levels to validate their effectiveness.

The following environmental action level exceedances were reported to the CNSC in 2021:

- PHCF – 7 daily action level exceedances above 100 μg/L for the daily composite sample uranium result from the combined facility discharge in 2021 (October 31, November 7, 17, 18, 25, 27 and 28). These occurrences were attributed to groundwater infiltration from heavy precipitation events. Cameco has implemented corrective actions and is continuing to repair and upgrade sections of the sanitary sewer network as part of the VIM project.

CNSC staff concluded that there was no impact to workers, the public or the environment as a result of these action level exceedances. CNSC staff reviewed the licensee’s corrective actions in relation to the exceedances and are satisfied with the licensee’s responses.

Environmental management system

The CNSC requires each licensee to develop and maintain an environmental management system (EMS) that provides a framework for integrated activities related to environmental protection. The EMS is described in the environmental management program and includes activities such as the establishment of annual environmental objectives, goals and targets. Licensees conduct internal audits of their programs at least once a year. As part of regular compliance verification, CNSC staff review and assess these objectives, goals and targets. CNSC staff determined that the UNSPFs established and implemented their EMSs in compliance with CNSC regulatory requirements.

Assessment and monitoring

CNSC staff verify that UNSPFs have environmental monitoring programs commensurate with the risks of the operations at each of their facilities. The environmental monitoring programs are designed to monitor releases of radioactive and hazardous substances, and to characterize the quality of the environment associated with the licensed facility. CNSC staff determined that the UNSPFs established and implemented environmental monitoring programs in compliance with CNSC regulatory requirements, where applicable.

Environmental risk assessment

Environmental risk assessment (ERA) is a systematic process used by licensees to identify, quantify, and characterize the risk posed by contaminants and physical stressors in the environment on human and other biological receptors, including the magnitude and extent of the potential effects associated with a facility.

ERAs provide the basis for the scope and complexity of environmental monitoring programs at UNSPFs.

Facility ERAs are to be reviewed on a 5-year cycle, or more frequently if major facility changes are proposed that would trigger a predictive assessment.

Protection of people

The CNSC requires licensees to demonstrate that the health and safety of the public are protected from exposures to hazardous (non-radiological) substances released from their facilities. Licensees use effluent and environmental monitoring programs to verify that releases of hazardous substances do not result in environmental concentrations that may affect public health. CNSC staff receive reports of discharges to the environment in accordance with reporting requirements outlined in the licence and the LCH. Based on assessments of the programs at the UNSPFs, CNSC staff concluded that the public continues to be protected from facility emissions of hazardous substances.

Estimated dose to the public

The maximum dose to the public from licensed activities is calculated by considering monitoring results from air emissions, liquid effluent releases and gamma radiation. The CNSC’s requirement to follow the ALARA principle, taking into account social and economic factors, means that licensees must monitor their facilities and keep doses to the public below the annual public dose limit of 1 millisievert per year (mSv/year) prescribed in the Radiation Protection Regulations Footnote 3.

Table H-1 of Appendix H compares estimated public doses from 2017 to 2021 for the UNSPFs. Estimated doses to the public from all these facilities continued to be well below the regulatory annual public dose limit of 1 mSv/year.

Conclusion

CNSC staff concluded that the UNSPFs have implemented their environmental protection programs satisfactorily for the reportable year. The licensees’ programs are effective in protecting the health and safety of people and the environment. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.10 Emergency management and fire protection

The emergency management and fire protection SCA covers emergency plans and emergency preparedness programs that exist for emergencies and for non-routine conditions.

CNSC staff assess performance in the emergency management and fire protection SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. Specific areas assessed within this SCA include licensee response to conventional and nuclear events, both onsite and offsite, and events that can affect the facility. CNSC staff ensure that comprehensive fire protection programs are also in place to minimize the risk to the health and safety of persons and to the environment from fire, through appropriate fire protection system design, fire safety analysis, fire-safe operation and fire prevention.

NNCs from inspections related to the emergency management and fire protection SCA were issued for the following licensees over the reporting period:

- BRR – 5 NNCs related to voice communication systems, emergency response team (ERT) medical evaluations, ERT training and qualifications, contamination control measures, and timeliness of the notification to the CNSC duty officer during emergency exercises

- PHCH – 4 NNCs related to document control, ERT medical evaluations, and personal protective equipment requirements during emergency exercises

The licensees have taken all necessary corrective actions to address the above-noted NNCs. The findings were of low safety significance and did not affect the health and safety of workers, people, the environment, or the safe operation of the facilities.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained satisfactory ratings in the emergency management and fire protection SCA for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.11 Waste management

The waste management SCA covers internal waste-related programs that form part of the facility’s operations up to the point where the waste is removed from the facility to a separate waste management facility. This SCA also covers the planning for decommissioning.

CNSC staff assess performance in the waste management SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff ensure that the licensees properly manage wastes throughout the lifecycle of a nuclear facility, which includes maintaining an up-to-date waste inventory and ensuring continued waste tracking.

The CNSC requires that licensees have a decommissioning plan and financial guarantee to ensure that sufficient financial resources are available to fund all approved decommissioning activities. CNSC staff confirm that the financial guarantees remain valid, in effect, and sufficient.

NNCs from inspections related to the waste management SCA were issued for the following licensees over the reporting period:

- BRR – 2 NNCs related to waste disposal pathways for liquid combustible and contaminated combustible material waste

- PHCH – 1 NCC related to the physical integrity of waste drums

The licensees have taken all necessary corrective actions to address the above-noted NNCs. One of the findings at BRR was of low safety significance, while the other was of medium significance. The finding at PHCF was of low safety significance. The findings did not affect the health and safety of workers, people or the environment, or the safe operation of the facilities.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained and implemented satisfactory waste management programs for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.12 Security

The security SCA covers the programs required to implement and support the security requirements stipulated in the regulations, licence, orders, or expectations for the facility or activity.

CNSC staff assess performance in the security SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. Specific areas assessed within this SCA include programs and procedures relating to access control, response arrangements, security practices, cyber security, and drills and exercises. CNSC staff ensure that the security programs in place prevent the loss, unauthorized removal or sabotage of nuclear substances, nuclear materials, prescribed equipment and information

Security inspections and details of security arrangements with the licensees are protected and not publicly available. There were no NNCs from inspections related to the security SCA over the reporting period.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained and implemented satisfactory security programs for the applicable reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.13 Safeguards and non-proliferation

The safeguards and non-proliferation SCA covers the programs and activities required for the successful implementation of the obligations arising from the Canada/IAEA safeguards agreements, as well as all other measures arising from the Treaty on the Non-Proliferation of Nuclear Weapons (NPT).

CNSC staff assess performance in the safeguards and non-proliferation SCA by verifying licensee compliance through desktop reviews and in-field activities, including participation in IAEA verification activities (see table 4-1). CNSC staff verify that licensees meet Canada’s international safeguards obligations as well as other measures arising from the NPT. CNSC staff ensure that the licensees have implemented and maintained effective programs to allow the implementation of both safeguards measures and non-proliferation commitments.

CNSC staff continue to monitor facility compliance with REGDOC-2.13.1, Safeguards and Nuclear Material Accountancy Footnote 8. Licensees require a licence, separate from the licensing of their operations, for the import and export of controlled nuclear substances, equipment and information identified in the Nuclear Non-proliferation Import and Export Control Regulations Footnote 9

CNSC staff concluded that the UNSPFs Footnote 2 met regulatory requirements and maintained and implemented satisfactory safeguards and non-proliferation programs for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

6.14 Packaging and transport

The packaging and transport SCA covers the safe packaging and transport of nuclear substances to and from licensed facilities. CNSC staff assess performance in the packaging and transport SCA by verifying the compliance of licensee documents and programs through desktop reviews and through compliance verification inspections that are planned or reactive. CNSC staff ensure that all elements of package design, package maintenance, and the registration for use of certified packages are in compliance with the Packaging and Transport of Nuclear Substances Regulations, 2015 Footnote 10 and Transportation of Dangerous Goods Regulations Footnote 11.

An NNC from inspections related to the packaging and transport SCA was issued for the following licensee over the reporting period:

- PHCF – 1 NNC related to transportation categorization labelling

The licensee has taken corrective actions to address the above-noted NNC. The finding was of low safety significance and did not affect the health and safety of workers, people, or the environment.

CNSC staff concluded that the UNSPFs met regulatory requirements and maintained satisfactory ratings in the packaging and transport SCA for the reportable year. CNSC staff will continue to monitor performance through regulatory oversight activities pertaining to this SCA.

2 The safeguards and non-proliferation SCA is not applicable to SRBT as there is no licence condition for the facility. SRBT manages a small quantity of depleted uranium (below exemption quantity as per the Nuclear Substances and Radiation Devices Regulations) used as a storage medium for tritium, not for its radioactive properties.

7 Indigenous consultation and engagement

7.1 CNSC staff engagement activities

The UNSPFs in Canada fall within the traditional and/or treaty territories of many Indigenous Nations and communities (see appendix M). CNSC staff’s efforts in 2021 supported the CNSC’s ongoing commitment to meet its consultation obligations and build positive relationships with Indigenous peoples with interests in Canada’s UNSPFs. CNSC staff continued to work with Indigenous Nations, communities and organizations to identify opportunities for formalized and regular engagement throughout the lifecycle of these facilities, and welcomed the opportunity to meet with Indigenous Nations and communities to discuss and address topics of interest or concern. CNSC staff also followed up with Curve Lake First Nation (CLFN) and the Algonquins of Ontario after the 2020 UNSPF ROR Commission meeting to further discuss their interventions and address their comments.

In 2021, CNSC staff’s engagement with Indigenous Nations and communities included conducting engagement activities specific to relevant licensing and Commission hearing processes, such as the June 2021 BWXT Medical licence application, the November 2021 BRR licence renewal, the November 2022 CFM licence renewal, and the April 2022 SRBT licence renewal. CNSC staff’s engagement in relation to each of these applications and regulatory processes included notifying identified Nations and communities about the application, sharing information about opportunities to participate and get involved, hosting meetings, making funding available through the CNSC’s Participant Funding Program (PFP), providing regular updates, and offering to meet to discuss any questions or concerns.

To ensure that all identified Indigenous Nations and communities (see appendix M) were made aware of this 2021 ROR, CNSC staff provided them with a notice of the PFP opportunity to review and comment on the ROR, as well as the opportunity to submit a written intervention and/or appear before the Commission as part of the Commission meeting. CNSC staff sent copies of this report to all Indigenous Nations, communities and organizations who had requested that they be kept informed of activities at the facilities covered in this report. CNSC staff also held meetings and scheduled a webinar in September 2022 with the identified Nations and communities to discuss the ROR and answer any related questions.

7.2 CNSC–Curve Lake First Nation long-term engagement terms of reference

As committed to with CLFN as part of the terms of reference (ToR) for long-term engagement with the CNSC, the update below was prepared in collaboration with CLFN representatives.

In 2020, CNSC staff started discussions with CLFN to establish a formal long-term relationship with the community, and ToR were signed between CLFN and the CNSC in February 2021. The ToR ensure that CLFN is provided with adequate and meaningful funding, support and capacity to participate in consultation and engagement activities required throughout the year. As part of the ToR, a yearly work plan is developed between the CNSC and CLFN, which provides information on the scope of work, detailed activities, and timelines associated with work items for collaboration and engagement.

In 2021, the work plan included:

- ToR maintenance and updates

- participation in the CNSC’s Independent Environmental Monitoring Program (IEMP)

- updates and discussions on specific projects and ongoing operations of existing nuclear facilities of interest (including the Darlington and Pickering nuclear generating stations and waste management facilities)

- co-jurisdictional matters of significance (i.e., Fisheries Act authorization, emergency preparedness, and thermal emissions from nuclear generating stations)

- information, communication and other topics (i.e., regulatory document updates, feedback on CNSC reporting and processes, PFP opportunities)

- developing a plan for a Curve Lake Indigenous knowledge and land use study

Even though the last item of the plan was not completed in 2021, CLFN and the CNSC are committed to developing a plan for a Curve Lake Indigenous knowledge and land use study in 2022. In 2021, CLFN and CNSC staff continued to meet monthly and work collaboratively to make progress on a number of the agreed-upon initiatives in the work plan. Through these meetings and interactions, CLFN and the CNSC have developed a good working relationship – one that has been more conducive to open and direct communication.

Topics of discussion included updates and conversations related to BWXT NEC (Toronto and Peterborough), PHCF and CFM. CNSC staff and CLFN also met to discuss CLFN’s involvement in the 2021 IEMP sampling campaign near the BWXT NEC site in Peterborough. In June 2021, CLFN observers participated in the IEMP sampling activities around that site. Having CLFN representatives participate in the sampling promotes a better understanding of sampling methods and improves input into future sampling in terms of CLFN species of interest, valued components, and potential sampling locations. CLFN also indicated its appreciation for participating in the sampling activities as it allows CLFN to better understand how the IEMP works and share insightful knowledge.

In 2021, CLFN provided feedback through its intervention on the 2020 RORs, and it continues to do so through ongoing discussions. CNSC staff have made a number of improvements to reports and documentation based on the feedback, such as including land acknowledgements for each facility and creating a separate Indigenous consultation and engagement section.

CNSC staff and CLFN continue to be committed to strengthening the relationship through ongoing, respectful dialogue to share knowledge, information on culture and history, and perspectives that help CNSC staff and CLFN learn from each other. CNSC staff will also continue to have discussions on areas of interest and on issues or concerns related to existing CNSC-regulated nuclear activities of interest to CLFN.

In 2022, CLFN and CNSC staff plan to initiate discussions and collaboration on a territory-wide study on Indigenous knowledge and land use as it relates to CNSC-regulated facilities and activities. Discussions will include the specific funding and capacity needs in order for CLFN to be able to meaningfully participate and complete these important studies and research. CLFN and CNSC staff will also continue to foster and create a safe ethical space for Indigenous knowledge to be collected and shared.

7.3 CNSC–Mississaugas of Scugog Island First Nation long-term engagement terms of reference

As committed to with the Mississaugas of Scugog Island First Nation (MSIFN) as part of the ToR for long-term engagement with the CNSC, the update below was prepared in collaboration with MSIFN representatives.

In September 2021, CNSC staff and MSIFN representatives started discussions to establish ToR for long-term engagement. The ToR were signed in March 2022, providing a formalized structure for ongoing dialogue on CNSC-regulated facilities and activities of interest in the MSIFN’s traditional and treaty territories. As part of the ToR, a yearly work plan was developed between the CNSC and MSIFN that provides information on the scope of work, detailed activities, and timelines associated with work items for collaboration and engagement. The 2022 work plan includes activities that CNSC staff and MSIFN will be working to implement throughout 2022 and beyond, including:

- participation in the CNSC’s IEMP

- collaborative annual reporting to the Commission and to the MSIFN Chief and Council

- updates and discussions on specific projects and ongoing operations of licensed nuclear facilities of interest

- enhanced information sharing and communication between the CNSC and MSIFN members

- emergency management and preparedness

The following facilities covered in this ROR are of interest in the work plan: PHCF, CFM, and BWXT NEC Toronto and Peterborough. CNSC staff and MSIFN are committed to continuing to strengthen the relationship through ongoing, respectful dialogue to share knowledge, information on culture and history, and perspectives that help CNSC staff and MSIFN learn from each other. CNSC staff will also continue to have discussions on areas of interest and concern related to CNSC-regulated nuclear activities of interest to MSIFN.

7.4 Licensee engagement activities

In 2021, CNSC staff continued to monitor the engagement work conducted by the UNSPF licensees to ensure that there was active engagement and communication with Indigenous Nations and communities interested in their facilities, and that activities were carried out in relation to the relevant licensing and Commission hearing processes that occurred in 2021.

CNSC staff confirmed that the licensees have Indigenous engagement and outreach programs. Throughout 2021, the UNSPF licensees met and shared information with interested Indigenous Nations, communities and organizations. Engagement efforts included emails, letters and meetings, as well as site visits and tours upon request. The CNSC encourages licensees to continue to develop relationships and engage with Indigenous groups who have expressed an interest in their activities.

8 Events and other matters of regulatory interest

8.1 Reportable events

Detailed requirements for reporting unplanned situations or events at UNSPFs to the CNSC are included in the applicable LCH. CNSC REGDOC-3.1.2, Reporting Requirements for Non-Power Reactor Class I Nuclear Facilities and Uranium Mines and Mills Footnote 12, came into force for UNSPFs in January 2019. Over the period covered by this report, licensees complied with the event reporting requirements of REGDOC-3.1.2.

CNSC staff are satisfied with licensees’ responses to reportable events. Licensees conducted investigations and/or implemented corrective actions for all reportable events, described below, to the satisfaction of CNSC staff. As a result, CNSC staff concluded that all UNSPFs managed operations safely and that there were no impacts to workers, the public or the environment.

Appendix L provides a summary of the reportable events that occurred at each facility over the review period. In total, there were 21 events reported in 2021, as described below, and none had an impact on the environment, the health and safety of persons, or the maintenance of national or international security.

BRR

- On November 1, 2021, a transport truck carrying uranium ore concentrate rolled backwards into a ditch at the edge of the parking lot when attempting to leave the Broken Canoe Trading Post in Mississauga First Nation near Blind River. There was no damage, injuries, or releases of nuclear material.

- On December 20, 2021, a tractor-trailer carrying 4 empty UO3 bins from the Port Hope Conversion Facility to the Blind River Refinery was involved in a traffic accident on Highway 7 near Omemee. A vehicle attempted to pass the tractor-trailer, causing a collision with an oncoming vehicle that subsequently hit the tractor. There was no damage, injuries, or releases of nuclear material.

PHCF

- On April 17, 2021, a small release of argon occurred from a valve on a tank outside Building 22. An investigation determined that the tank pressure was slightly higher than normal following the previous tank filling, causing the valve to open to release pressure as designed. Approximately 10 m3 was released before a contractor closed the valve. With the tank pressure reduced to normal, the valves were re-opened and there was no further leakage. Additional actions were not required since the tank operated as intended.

- On June 3, 2021, the ERT was activated in response to a UO2 discharge from a vacuum exhaust system at Building 24. An investigation determined that the vacuum system collector was overfilled, forcing the contents to be discharged to the environment. Samples were taken around Building 24 to verify that the release was localized to the area immediately outside the exhaust line. It was estimated that less than 1 g of uranium was released. The vacuum system was taken out of service and restarted once the follow-up corrective actions were completed by Cameco.